Laser cutting machine is an automated equipment that uses high energy density laser beam to accurately cut various types of plates. Its core advantages are non-contact, high precision and high efficiency. It is widely used in industrial manufacturing and various plate processing scenarios.

Laser cutting machine is an automated equipment that uses high energy density laser beam to accurately cut various types of plates. Its core advantages are non-contact, high precision and high efficiency. It is widely used in industrial manufacturing and various plate processing scenarios.

A handheld laser marking machine is a portable laser marking device. Its core is to focus a high-energy laser beam on the surface of a material through a handheld laser emitting unit, causing physical or chemical changes in the material, thereby forming a permanent and fine mark.

The CO2 laser marking machine is a device that uses laser light (wavelength 10.6μm) generated by carbon dioxide gas to mark materials. The core of the device is to rely on the thermal effect of the laser to vaporize, carbonize or change the color of the material surface to form text, patterns, QR codes, etc.

The UV laser marking machine is a high-end cold-process marking device that uses a UV laser. Its core principle is photochemical rather than photo thermal. Because UV photons are extremely energetic, they can directly destroy chemical bonds on the surface of materials (especially polymers), causing chemical changes rather than melting or vaporization. This achieves ultra-fine, "cold" marking effects. This process leaves a minimal heat-affected zone, hence the name "cold processing."

The robot arm welding machine is a highly automated welding system. Its core is a multi-jointed industrial robotic arm with a welding tool (welding gun) mounted on the end of the arm. This system, controlled by computer programming, can automatically perform precise, repetitive welding tasks, making it suitable for large-scale, high-quality production environments.

Wall Reinforcement

In construction, the stability of walls is of utmost importance. Welded wire meshes produced by welded mesh machines play a crucial role in wall reinforcement. These meshes are formed by welding longitudinal and transverse steel bars together to create a regular grid structure. In brick - concrete structures or frame - infilled walls, laying welded wire meshes inside the walls can enhance the overall strength and crack - resistance of the walls. For example, in earthquake - prone areas, using welded wire meshes to reinforce walls can effectively improve the seismic performance of buildings and reduce the risk of wall cracking or even collapse during an earthquake. They can evenly distribute the stress borne by the walls, making the walls more stable when subjected to external forces.

Slope Protection

For slope protection in construction projects, chain - link wire meshes produced by chain - link mesh machines and woven wire meshes are widely used. Chain - link wire meshes have good flexibility and impact resistance, and they can adapt to slopes of different shapes and gradients. Laying chain - link wire meshes on the slope surface and fixing them with anchor rods can prevent soil and stones on the slope from sliding, thus stabilizing the slope. Woven wire meshes can achieve similar protective effects. Their woven structure can provide a certain buffering effect and absorb the energy of rainwater scouring and external impacts. In construction projects in mountainous areas, slope protection is vital for ensuring the safety of surrounding roads and buildings, and chain - link and woven wire meshes have become commonly used protective materials.

Fencing and Isolation

Around construction sites and in some areas that need isolation, products made by expanded metal mesh machines and barbed wire machines play the role of fencing and isolation. Expanded metal meshes have high strength and good protective performance, and they can be used as fences around construction sites to prevent unauthorized personnel from entering, ensuring construction safety and order. Barbed wire is usually used in areas with high security requirements, such as prisons and military facilities. In the construction industry, for areas where valuable building materials are stored or where there are special security requirements, barbed wire is also used for enhanced protection to act as a deterrent and barrier.

1. Welded Mesh Machines

They are mainly used for wall reinforcement within building structures. The welded wire meshes they produce are large in size and have regular grids, which can provide large - area and uniform support for walls. Since the diameter of the steel bars and the mesh spacing of welded wire meshes can be adjusted according to different architectural design requirements, they can perform well in different types of wall reinforcement. For example, in the wall construction of large commercial buildings and residential buildings, welded wire meshes produced by welded mesh machines are commonly used reinforcement materials. Their advantage lies in their ability to combine well with construction materials such as concrete and enhance the overall performance of the walls.

2. Chain - Link Mesh Machines and Woven Wire Mesh Equipment

They are mainly applied in slope protection and temporary fencing scenarios. The chain - link wire meshes produced by chain - link mesh machines are flexible and suitable for being laid on irregular slope surfaces. Their diamond - shaped mesh structures can effectively disperse external forces. Woven wire meshes are more commonly used in some temporary fencing scenarios where a certain degree of aesthetics is required, such as temporary isolation around landscape construction projects. Their characteristics include easy and quick installation, the ability to be cut and adjusted according to actual on - site conditions, and relatively low cost, making them suitable for large - scale slope protection projects and temporary isolation needs.

3. Expanded Metal Mesh Machines

They are mainly used for permanent fencing around construction sites and in areas that require high - strength protection. Expanded metal meshes are strong and stable and can withstand large external impacts. During the long - term use of construction projects, they can effectively protect the safety of construction sites and prevent theft and vandalism. For example, in some large industrial construction projects, expanded metal mesh fences can provide reliable protection for on - site equipment and materials.

4. Barbed Wire Machines

They are specifically used for isolating areas with extremely high security requirements. Barbed wire has a strong deterrent effect and can effectively prevent people from climbing over illegally. In the construction industry, although their application scenarios are relatively limited, in areas involving important facilities or the storage of high - value items, barbed wire is an indispensable security measure, providing additional security for construction projects.

Automotive Manufacturing

In automotive manufacturing, laser welding machines play a crucial role in multiple aspects. For the production of engine components, high - precision and high - strength welding is required. Engine parts such as cylinder heads and crankshafts need to be welded with great accuracy to ensure proper functionality and durability. Laser welding can achieve fine and strong welds, minimizing the risk of leakage and mechanical failures. For the body - in - white construction, laser welding is used to join different steel or aluminum alloy panels. This helps in creating a lightweight yet rigid structure, improving fuel efficiency and vehicle safety. Welding the roof to the side panels or the floor pan components demands both speed and quality, which laser welding can effectively provide.

Electronic Device Manufacturing

When it comes to manufacturing electronic devices like smartphones, laptops, and tablets, laser welding is employed for joining internal metal components. For instance, the connection of circuit board components, battery contacts, and metal casings. The small size and delicate nature of these components require a welding method that causes minimal heat damage to the surrounding areas. Laser welding's ability to deliver high - energy density in a precise spot makes it an ideal choice. It can create reliable electrical connections and ensure the structural integrity of the device without affecting the functionality of adjacent electronic elements.

Machinery and Equipment Manufacturing

In the production of industrial machinery and equipment, laser welding is used for fabricating large - scale metal structures and components. For example, in the manufacturing of heavy - duty construction machinery, such as excavators and bulldozers, laser welding is used to join thick metal plates for the main frames and boom arms. This provides the necessary strength and stability for these machines to operate under extreme conditions. In the case of precision machinery like CNC machine tools, laser welding is used for assembling small and high - precision parts, ensuring accurate alignment and smooth operation.

1. Handheld Laser Welding Machine

The handheld laser welding machine offers high flexibility. It is suitable for on - site repair and maintenance tasks in the manufacturing industry. For example, when a part of an automotive production line breaks down and requires immediate welding repair, technicians can quickly bring the handheld laser welding machine to the site and perform the welding operation. In small - batch production or prototyping, where the welding tasks may vary in location and complexity, the handheld laser welding machine allows operators to adapt to different situations easily. However, its welding precision depends largely on the operator's skill level, and the welding speed is relatively slow. So, it is not recommended for large - scale, high - volume production with strict precision requirements. When you need to make quick repairs on the go or deal with small - scale, non - standardized welding jobs in a manufacturing environment, the handheld laser welding machine is the way to go.

2. Automatic Platform Laser Welding Machine

The automatic platform laser welding machine is designed for large - scale, standardized production. In automotive body - in - white production lines, where thousands of identical welding tasks need to be carried out with high precision and consistency, the automatic platform laser welding machine shines. It can be programmed to follow specific welding paths and parameters, ensuring that each weld is of the same high quality. By using fixtures and conveyors, it can handle a continuous flow of workpieces, greatly improving production efficiency. But it lacks flexibility when dealing with irregularly shaped or non - standard workpieces. If your manufacturing process involves mass - producing standardized parts with relatively simple geometries and requires high - speed, high - precision welding, the automatic platform laser welding machine is the optimal choice.

3. Robot Arm Welding Machine

The robot arm welding machine combines flexibility and automation. It can move freely in three - dimensional space, making it ideal for welding complex - shaped workpieces. In the manufacturing of aerospace components or high - end machinery with intricate geometries, the robot arm can be programmed to follow the exact contours of the parts, ensuring perfect welds. It can also be quickly reprogrammed to adapt to different production tasks, providing a high degree of versatility. Although it has a relatively high initial cost and requires skilled programming and maintenance, for manufacturing processes that involve welding complex parts with changing production requirements, the robot arm welding machine is the most suitable option.

Consumer Goods Industry

In the consumer goods industry, laser marking machines are widely used for product identification and branding. For example, on smartphones, laser marking is used to engrave brand logos, model numbers, and serial numbers on the back covers or frames. This provides a permanent and high - quality mark that is resistant to wear and tear, ensuring product authenticity and traceability. In the case of home appliances like refrigerators, washing machines, and televisions, laser marking is used to mark important information such as product specifications, safety instructions, and manufacturing dates. This helps consumers to quickly and accurately identify product details and also aids in after - sales service and product recalls.

Packaging Industry

Laser marking is becoming increasingly popular in the packaging industry. For food and beverage packaging, it is used to mark expiration dates, batch numbers, and barcodes on various packaging materials such as plastic bottles, cardboard boxes, and metal cans. The non - contact nature of laser marking ensures that the packaging integrity is maintained, and there is no risk of contamination. In the cosmetics and personal care product packaging, laser marking is used to create elegant and long - lasting brand markings and product information, enhancing the overall aesthetic appeal of the products.

Jewelry and Gift Industry

In the jewelry and gift industry, laser marking machines are used to add personalized and decorative elements. For jewelry items like rings, necklaces, and bracelets, laser marking can be used to engrave names, initials, or special messages, making the pieces more unique and meaningful. In the case of high - end gifts such as watches and luxury pens, laser marking is used to create intricate patterns and brand emblems, adding a touch of sophistication.

1. Fiber Laser Marking Machine

The fiber laser marking machine is well - suited for marking on metal materials in daily life. In the consumer goods industry, when marking on metal parts of smartphones, such as the metal frames or connectors, the fiber laser marking machine can produce clear, high - contrast marks with high precision. It can also be used for marking on metal household items like cutlery, where a durable and long - lasting mark is required. Due to its high peak power and good beam quality, it can achieve fast marking speeds, making it ideal for large - scale production environments where high productivity is crucial. When your daily life - related manufacturing or customization involves marking on metals and requires high - speed and high - quality marking, the fiber laser marking machine is the preferred choice.

2. UV Laser Marking Machine

The UV laser marking machine is mainly used for marking on sensitive materials. In the packaging industry, when marking on plastic food packaging or labels, the UV laser's low heat input ensures that the plastic does not deform or discolor. It is also suitable for marking on glass products, such as perfume bottles or glassware, where a fine and precise mark is desired without causing any damage to the surface. In the jewelry and gift industry, for marking on gemstones or delicate materials, the UV laser marking machine can create intricate designs without affecting the material's integrity. If you are dealing with materials that are heat - sensitive or require extremely fine and high - precision marking in daily life applications, the UV laser marking machine is the right option.

3. CO₂Laser Marking Machine

The CO₂laser marking machine is ideal for marking on non - metal organic materials. In the packaging industry, it can mark on cardboard boxes, paper labels, and wooden packaging with ease. It is also commonly used for marking on leather products, such as wallets, belts, and shoes, creating beautiful and long - lasting patterns and brand markings. In the home decor industry, for marking on wooden furniture or bamboo products, the CO₂ laser marking machine can add decorative elements and product information. When your daily life - related marking tasks involve non - metal organic materials and you need a reliable and cost - effective marking solution, the CO₂ laser marking machine is a good choice.

During the machining process, air compressors play a crucial role. For instance, in metal cutting operations such as milling, drilling, and turning, compressed air is used to power pneumatic tools. Pneumatic drills, pneumatic grinders, etc., are driven by compressed air, which can provide stable and powerful power output, making the machining process more efficient. Moreover, compressed air can be used to remove chips generated during machining, keeping the machining area clean and improving machining accuracy and quality. In mold manufacturing, pneumatic demolding devices use the pressure of compressed air to smoothly eject the molded products from the molds, preventing product damage.

Automobile Manufacturing

Multiple stages of automobile manufacturing rely on air compressors. In the welding process of automobile bodies, some automated welding equipment adopts pneumatic control systems. Compressed air is used to drive the joint movements of welding robots, ensuring the accuracy of welding positions and the stability of the welding process. In the automobile painting workshop, compressed air is used for the atomization operation of spray guns, evenly spraying paint on the car body surface to make the coating more smooth and improve the vehicle's appearance quality. Additionally, pneumatic tightening tools like pneumatic wrenches on the automobile assembly line are used to tighten various bolts and nuts, ensuring the fastening degree of automobile components.

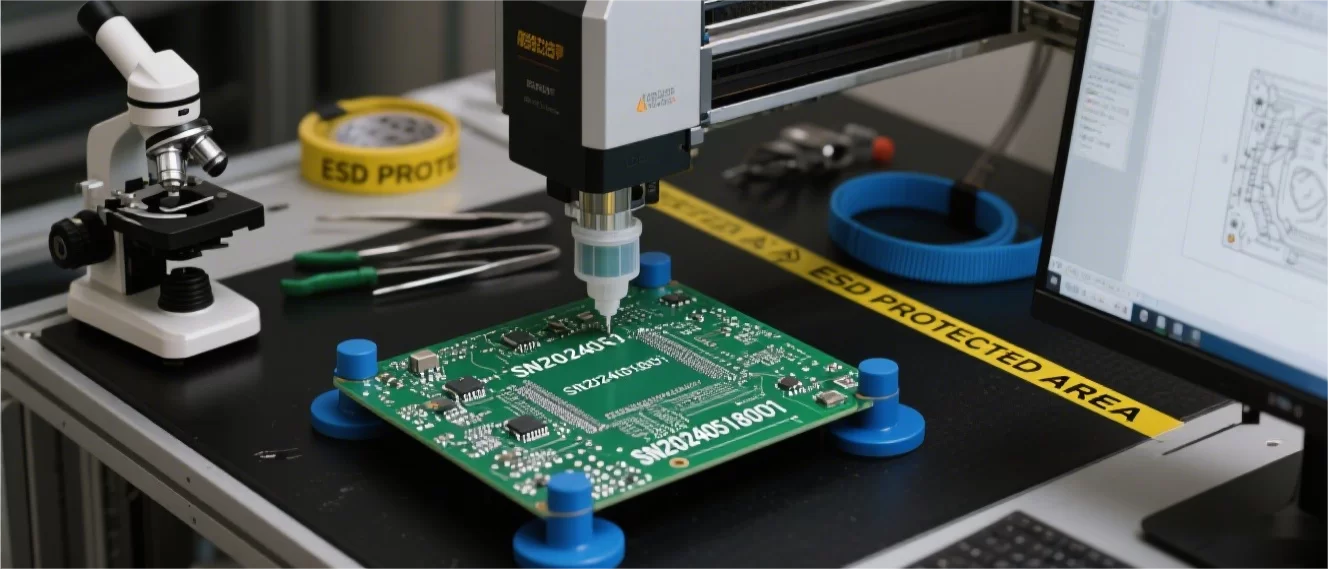

Electronics Manufacturing

In the electronics manufacturing industry, air compressors are also of great importance. Since electronic components are extremely precise and require a high - quality production environment, purified compressed air can be used in the packaging process of electronic chips, providing a stable air source for packaging equipment and ensuring the sealing and reliability of chip packaging. During the manufacturing process of printed circuit boards, compressed air is used to clean dust and impurities on the board surface, guaranteeing the electrical performance of the circuit boards. Meanwhile, some electronic testing equipment also relies on compressed air to achieve specific testing functions.

1. Piston Air Compressors

Piston air compressors compress air through the reciprocating motion of pistons in cylinders. Their advantages are simple structure and low cost, making them suitable for some small - scale manufacturing enterprises or occasions where the quality requirements for compressed air are not extremely high. In some small machining workshops, piston air compressors can power pneumatic tools to meet the daily simple machining needs. However, their air displacement is relatively small, and they generate large vibrations and noises during operation, so they are not suitable for large - scale production scenarios with high requirements for the working environment.

2. Screw Air Compressors

Screw air compressors are divided into twin - screw and single - screw types. They have the advantages of large air displacement, stable operation, small vibrations, and low noise. They are widely used in automobile manufacturing and large - scale machining enterprises. Twin - screw air compressors are especially suitable for occasions with continuous and stable air supply and can meet the air consumption needs of numerous pneumatic devices on large - scale production lines such as automobile assembly lines. Their high reliability and low maintenance cost make them an ideal choice in the manufacturing industry.

3. Centrifugal Air Compressors

Centrifugal air compressors use high - speed rotating impellers to accelerate gas and then convert kinetic energy into pressure energy through diffusers. They have a very large air displacement and are suitable for large manufacturing enterprises and occasions with extremely high requirements for the quality of compressed air. In the electronics manufacturing industry, after multi - stage purification and drying treatment, centrifugal air compressors can provide high - quality compressed air for dust - free workshops to meet the needs of high - precision production such as electronic chip manufacturing. However, the equipment investment and maintenance costs of centrifugal air compressors are high, and they require professional technicians for operation and maintenance.

Component Fabrication

In the metal industry, laser cutting machines are extensively used for fabricating various components. For automotive parts, they play a crucial role in creating body panels, brackets, and engine components. In the production of body panels like doors and hoods, laser cutting provides high precision, ensuring a perfect fit during assembly. For engine components, the ability to cut complex shapes with tight tolerances is essential for proper functioning. In the aerospace sector, laser - cut metal parts are used in aircraft frames, wings, and engine turbines. These parts require extreme precision and high - quality cuts to meet the strict safety and performance standards of the aerospace industry.

Structural Fabrication

For large - scale metal structures such as bridges, buildings, and industrial machinery frames, laser cutting is employed. In bridge construction, laser - cut steel beams and plates are used to create the framework. The precision of laser cutting ensures that the components fit together accurately, reducing the need for on - site adjustments and improving the overall structural integrity. In building construction, metal studs, trusses, and curtain wall components are often fabricated using laser cutting. Industrial machinery frames also benefit from laser cutting, as it allows for the creation of custom - designed components with high strength and precision.

Decorative Metalwork

Laser cutting is also popular in creating decorative metal items. In architectural decoration, laser - cut metal screens, grilles, and facades add an aesthetic touch to buildings. The ability to cut intricate patterns and designs on metal sheets or tubes makes it possible to create unique and visually appealing structures. In the production of high - end furniture and interior design elements, laser - cut metal parts are used to enhance the overall look and feel of the space.

1. Laser Sheet - Metal Cutting Machines

Automotive Body Panels and Large - Scale Plates

In the automotive industry, laser sheet - metal cutting machines are mainly responsible for cutting flat body panels. These panels are large and require precise two - dimensional cutting to achieve the desired shape and size. In structural fabrication for buildings and bridges, they are used to cut large steel plates that form the base of the structures. For example, floor plates in high - rise buildings and the base plates of bridge piers are cut using these machines. In decorative metalwork, they are ideal for creating flat decorative elements such as metal wall art and large - scale metal screens.

Mass Production of Flat Components

Due to their ability to handle large flat sheets and perform high - speed, accurate cuts, laser sheet - metal cutting machines are well - suited for mass production of flat metal components. In industries where a large number of identical flat parts are needed, such as in the manufacturing of electrical enclosures or metal containers, these machines can significantly increase production efficiency.

2. Laser Tube - Cutting Machines

Automotive Exhaust Systems and Tubular Structures

In the automotive industry, laser tube - cutting machines are specifically used for cutting tubes for exhaust systems. These tubes need to be cut at specific angles and lengths, and may require holes or slots for proper installation. In industrial machinery, tubular components such as hydraulic pipes and conveyor system supports are cut using these machines. In decorative metalwork, they are used to create tubular decorative elements like metal railings and lamp posts, where the ability to cut patterns and shapes on the curved surface of the tube is essential.

Custom - Shaped Tubular Parts

When it comes to creating custom - shaped tubular parts with complex geometries, laser tube - cutting machines shine. They can rotate the tube during the cutting process, allowing for precise cuts at different orientations. This is particularly useful in industries such as aerospace, where tubular components with unique shapes are often required for fluid transfer systems and structural supports.

Laser welding machines represent a breakthrough in modern manufacturing technology, offering unmatched precision, speed, and efficiency.

In the realm of industrial manufacturing, the welded mesh making machine stands as a cornerstone of efficiency and precision, enabling the production of durable wire mesh products across diverse sectors.

In the evolving landscape of metal fabrication, SHIJIAZHUANG TOPSTAR INTERNATIONAL TRADING CO.,LTD is proud to highlight the technological prowess of the handheld laser welding machine—a game-changing tool redefining efficiency and precision in industrial welding.

In the realm of industrial manufacturing, the welded mesh making machine stands as a cornerstone of efficiency and precision, enabling the production of durable wire mesh products across diverse sectors.

In the evolving landscape of metal fabrication, SHIJIAZHUANG TOPSTAR INTERNATIONAL TRADING CO.,LTD is proud to highlight the technological prowess of the handheld laser welding machine—a game-changing tool redefining efficiency and precision in industrial welding.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.