In the realm of industrial manufacturing, the welded mesh making machine stands as a cornerstone of efficiency and precision, enabling the production of durable wire mesh products across diverse sectors. SHIJIAZHUANG TOPSTAR INTERNATIONAL TRADING CO.,LTD is proud to showcase how this advanced equipment, backed by parent company Yingyi Machinery’s engineering heritage, delivers tailored solutions for infrastructure, safety, and agriculture—redefining standards for reliability and adaptability.

Applications: From Skyscrapers to Farmlands

The welded mesh making machine’s versatility shines through its ability to produce customized mesh for critical applications:

Construction & Infrastructure: As highlighted in the projects, reinforced welded mesh plays a pivotal role in concrete structures. Our machines fabricate high-tensile steel mesh (wire diameter 6–12mm) with precise 100x100mm or 150x150mm grids, used in bridge decks, airport runways, and high-rise foundations. These meshes enhance concrete bonding, reducing cracks by 40% compared to traditional rebar. A recent project for a Dubai skyscraper utilized our machine to produce 2.5m-wide mesh panels, accelerating construction timelines by 25% .

Industrial Safety: Compliance with OSHA and ANSI standards is non-negotiable in factory settings. Our welded mesh making machine manufactures 1¼”x1¼” rectangular mesh panels from 10-gauge steel, ideal for machine guarding and conveyor enclosures. These panels, often 3ft x 8ft in size, are 50% faster to install than competitors’ products, providing instant protection for workers while maintaining equipment accessibility .

Agriculture & Animal Husbandry: Farmers and breeders rely on our machines to create corrosion-resistant galvanized mesh for livestock cages (chicken coops, rabbit hutches) and crop enclosures. The adjustable mesh sizes (50–300mm) prevent predator intrusion while ensuring ventilation, with a single machine producing up to 500 cages weekly for a major Indian agricultural cooperative.

Transportation Infrastructure: Highway and railway projects demand robust fencing to prevent accidents. Our welded mesh making machine produces 3m-wide (guardrail mesh) with 2.5–6mm wire, featuring interlocking designs that withstand extreme weather. A recent order for Thailand’s motorway expansion included 10km of such mesh, installed to reduce wildlife-vehicle collisions by 60% .

How It Works: Precision Engineering in Action

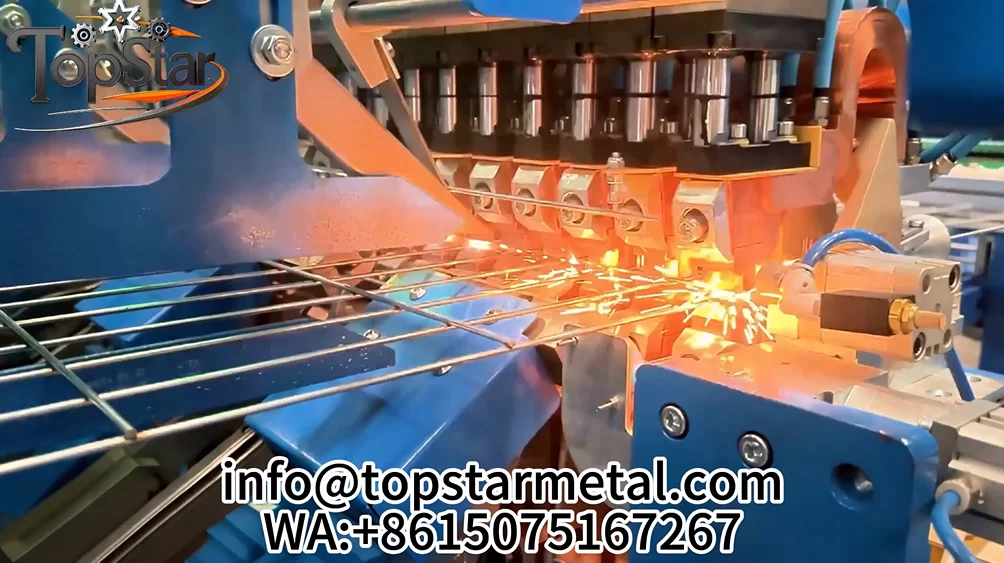

At its core, the welded mesh making machine merges mechanical precision with intelligent control systems to transform raw wire into structured mesh:

Wire Preparation: Coiled steel wires (mild steel, stainless steel, or galvanized) are fed into integrated straightening units, which remove curvature to ensure uniform alignment. (Longitudinal wires) are positioned automatically, while (Cross wires) are cut to length via precision shears—adjustable for mesh sizes from 50mm to 400mm .

Welding Process: Using power electronic synchronous control, the machine clamps wires at predefined intervals and delivers high-frequency current (via epoxy resin pouring transformers) to create strong, spatter-free (weld points). The PLC touchscreen system allows operators to program variable grid patterns—critical for projects requiring mixed hole sizes in a single panel. For example, a 2024 order for a European warehouse specified alternating 100mm and 150mm grids to balance load-bearing and material savings .

Automation & Quality Control: Advanced models feature servo-driven (mesh pulling mechanisms) that ensure grid accuracy within ±0.1mm. Sensors detect wire jams or misalignment, triggering automatic shutdowns to prevent defects. Post-welding, meshes undergo ultrasonic testing to verify weld integrity, meeting ISO 9001 standards .

Efficiency Enhancements: Modern welded mesh making machines boast production speeds of 50–75 welds per minute, with water-cooled transformers enabling 24/7 operation. A recent upgrade to our machines introduced automatic (mesh flipping systems), increasing stacking efficiency by 30% for large-scale orders .

As SHIJIAZHUANG TOPSTAR expands its global footprint, the welded mesh making machine remains a testament to our commitment to innovation. Whether for skyscrapers, factories, or farms, this equipment delivers the precision and reliability that clients worldwide trust. Contact our technical team to explore customized