Precision laser cutting machine utilizes a high-energy-density, precision laser beam as a "tool" to perform high-precision cutting on various materials. Its core advantages lie in its precision and flexibility.

Precision laser cutting machines are core equipment for high-precision and high-flexibility material processing in modern manufacturing. Their essence is to use a high-energy-density focused laser beam to replace traditional mechanical tools, and to complete cutting through the physical/chemical interaction between the laser and the material (such as vaporization, melting, and peeling).

1.Flexible & Efficient: Changing the program instantly switches cutting patterns, achieving cutting speeds of over 10m/min on 1mm stainless steel, suitable for a wide range of products and mass production.

2.Wide Material Compatibility: Capable of cutting metals, non-metals, and specialty materials (sapphire, carbon fiber, etc.), breaking through the limitations of traditional machining. No Tool Wear: Lasers experience no physical wear, and annual maintenance costs are only 1/3 to 1/2 of those of traditional equipment.

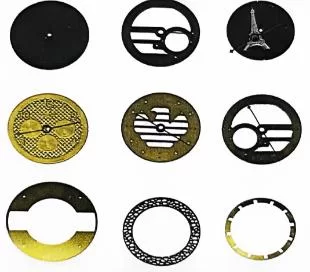

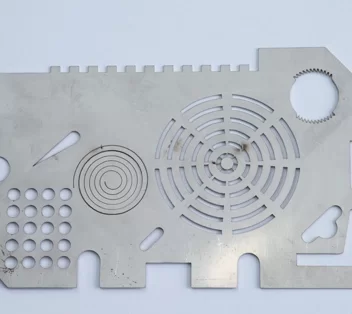

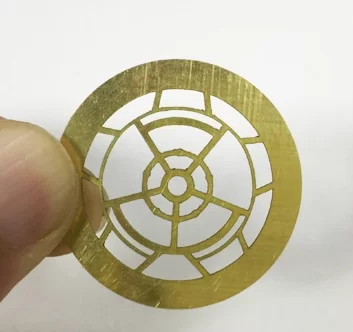

3.Capable of processing complex structures: Capable of cutting 0.01mm micro-holes, 0.02mm fine slits, and 3D special-shaped parts, pushing the boundaries of design.

Precision laser cutting machines are widely used in electronic information, medical equipment, automobile manufacturing, aerospace, consumer electronics, jewelry, packaging, photovoltaics and other fields, and are used for cutting and processing various high-precision materials.

Model series | MCT-6060 | ||||

model | MCT-6060-1000 | MCT-6060-1500 | MCT-6060-2000 | MCT-6060-3000 | MCT-6060-6000 |

Output power | 1000w | 1500w | 2000w | 3000w | 6000w |

type | continuous | ||||

Cutting product accuracy | 0.03 | ||||

Minimum hole diameter for cutting through holes | 0.1mm | ||||

Processing materials | Aluminum, copper, stainless steel metal materials | ||||

Effective cutting size | 600mm*600mm | ||||

Fixing method | Pneumatic clamping and fixture support | ||||

Drive system | linear motors | ||||

Positioning accuracy | +/-0.008mm | ||||

Repeatability | 0.008mm | ||||

CCD alignment accuracy | 10um | ||||

Cutting gas source | Air, nitrogen, oxygen | ||||

Cutting line width and fluctuation | 1.2KW | ||||

Cutting surface | Smooth, no burrs, no black edges | ||||

Machine warranty period | 1 year (excluding wearing parts) | ||||

weight | 1700Kg | ||||

Cutting speed | Stainless steel: 4MM (air) Aluminum plate: 2MM (air) Copper plate: 1.5MM (air) | Stainless steel: 6MM (air) Aluminum plate: 3MM (air) Copper plate: 3MM (air) | Stainless steel: 8MM (air) Aluminum plate: 5MM (air) Copper plate: 5MM (air) | Stainless steel: 10MM (air) Aluminum plate: 6MM (air) Copper plate: 6MM (air) | Stainless steel: 10MM (air) Aluminum plate: 8MM (air) Copper plate: 8MM (air) |

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.