Laser cutting machine is an automated equipment that uses high energy density laser beam to accurately cut various types of plates. Its core advantages are non-contact, high precision and high efficiency. It is widely used in industrial manufacturing and various plate processing scenarios.

Laser cutting machines are "efficient and precise tools" for modern sheet metal processing. With their flexibility and precision, they have gradually replaced traditional mechanical cutting and become core processing equipment in many industries.

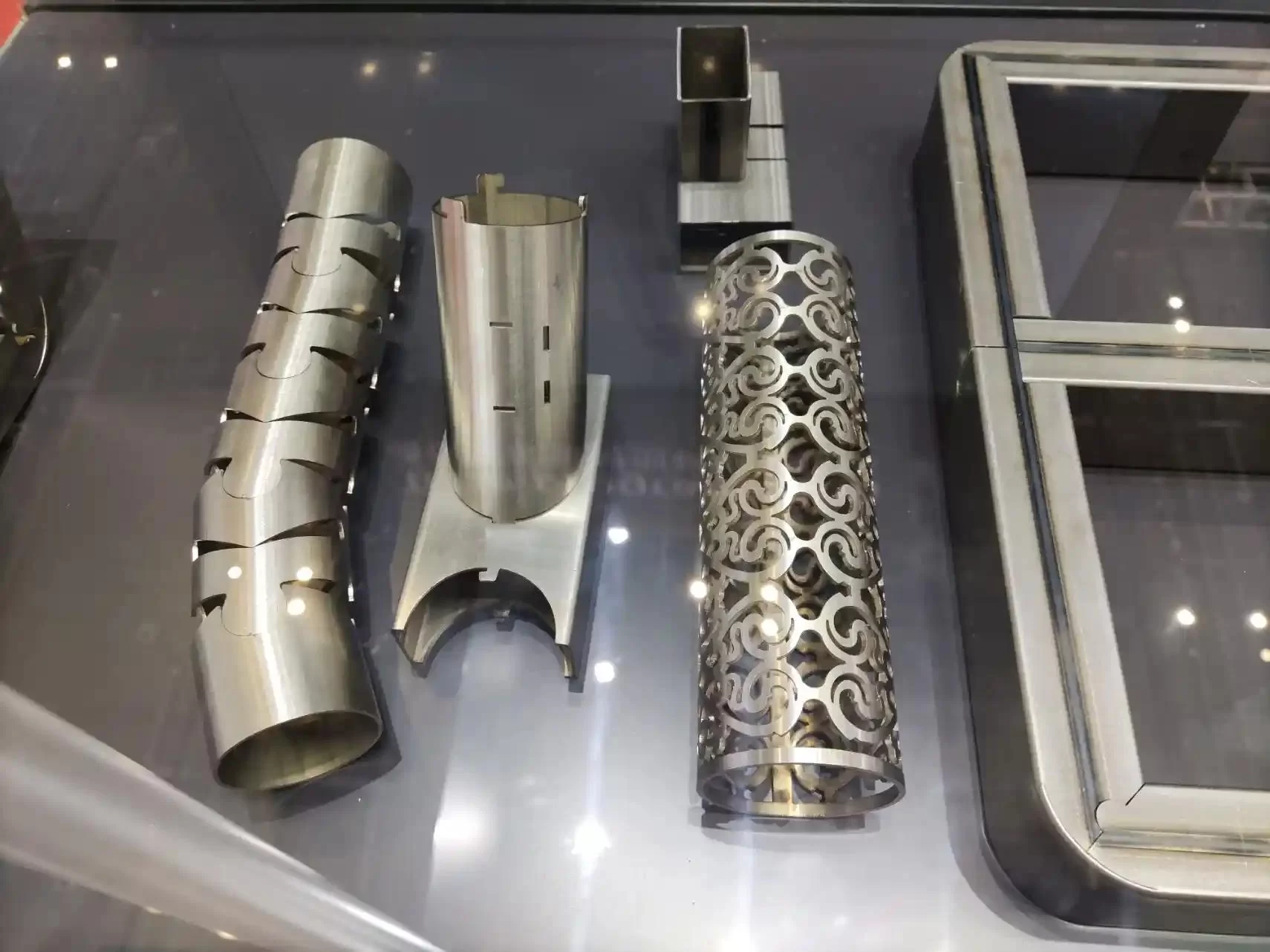

1.1High Precision: Small spot size, narrow kerf, and minimal error, suitable for complex patterns and precision parts.

2.Non-Contact, No Material Damage: No mechanical pressure, preventing material deformation and scratches, suitable for thin, fragile, or delicate sheets.

3.High Efficiency: High cutting speed for thin and medium sheets, eliminating frequent tool changes. CNC automatic operation reduces downtime.

4. Wide Compatibility: Simply change the laser type or adjust the parameters to cut metals and non-metals without having to change equipment.

5.Reduced Post-Processing: No additional grinding is required for trimming, resulting in minimal debris and reduced cleaning and secondary processing.

Laser cutting machines are widely used in industrial manufacturing, advertising decoration, furniture and building materials, medical electronics, cultural and creative packaging and other fields due to their adaptability to fiber laser cutting of metals and CO₂ laser cutting of non-metals, meeting the needs of precise or personalized processing of various types of plates.

Name | Paramerers | Unit |

Machine model | 1530 | |

Laser Source | Max6000 | w |

Water cooler Power | 6.0 | kw |

Software | Raytools | |

Guide | Taiwan | |

Rack | Vastun, Germany | |

Servo Motor | leadshine | |

Reducer | Japanese SHIMPO | |

Minimum cutting width | 0.08-0.1 | mm |

Maximum cutting thickness | 25Carbon steel 18stainless steel | mm |

Maximum moving speed | 100 | m/min |

Electricity requirements | 380/50,60 | v/hz |

Graphic Format Supported | PRO/E.UG, Solidworks | |

Acceleration | 1.0 | G |

Total power | 30 | kw |

Presser of N2/O2/AIR | 15-20/6-8/15-30 | bar |

Total Weight | 3.5 | t |

Work per day | 16 | h |

Lay out | 4.4*2.28*1.85 | m |

Oil Box | Auto Oil Injection System |

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.