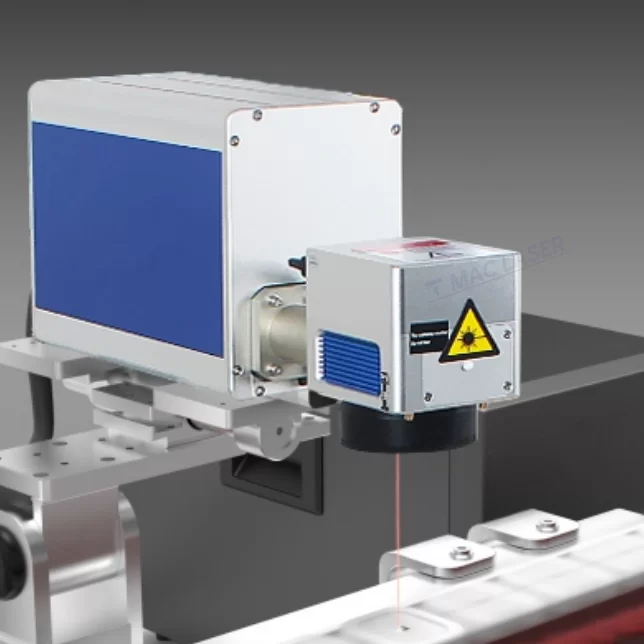

The UV laser marking machine is a high-end cold-process marking device that uses a UV laser. Its core principle is photochemical rather than photo thermal. Because UV photons are extremely energetic, they can directly destroy chemical bonds on the surface of materials (especially polymers), causing chemical changes rather than melting or vaporization. This achieves ultra-fine, "cold" marking effects. This process leaves a minimal heat-affected zone, hence the name "cold processing."

The UV laser marking machine is a high-end cold-process marking device that uses a UV laser. The key factors in choosing a UV laser marking machine are:

Material Type: If you are processing heat-sensitive non-metallic materials (such as plastics, PCBs, and glass) or metal products requiring ultra-fine marking, UV is the preferred choice.

Precision Requirements: If you require extremely high precision and aesthetics in your markings, a UV laser is a must.

Budget Considerations: If a fiber laser can achieve the desired results, provided the process requirements are met, it offers a more cost-effective solution. UV equipment is a solution for specific, high-end needs.

1."Cold Processing" Feature

This is its core advantage. The processing generates virtually no heat, avoiding thermal stress, thermal deformation, slag, and micro cracks in the material, achieving true "cold" marking.

2.Extremely High Processing Precision

The ultraviolet wavelength is extremely short, allowing it to be focused into an ultra-small spot diameter of less than 10 microns, enabling ultra-fine marking that is impossible with fiber and CO2 lasers.

3.Wide Material Compatibility (Particularly for non-metals)

It can process many heat-sensitive materials, a shortcoming of traditional fiber lasers.

4.Excellent Marking Results

Marking edges are crisp and clear, without any burrs or burns. A variety of effects can be produced on the material surface, including shallow and deep engraving, and surface color changes (such as white and gray), with high contrast and excellent aesthetics.

5.Consumables and Maintenance

While there are no consumables, UV lasers typically have a shorter lifespan than fiber lasers (approximately 15,000-20,000 hours), and the water cooling system requires maintenance, resulting in relatively high operating costs.

1. Electronics and Semiconductor Industry (largest application area)

(1)IC Chips: Marking tiny letters and logos on wafers and chips without thermal stress or damage.

(2)FPC/PCB: Marking QR codes and text on flexible printed circuits and PCBs with high precision and without damaging the substrate.

(3)Electronic Components: Fine coding on resistors, capacitors

2. Plastics and Polymer Materials:

(1)Plastic Buttons: Marking characters on mobile phones and remote control buttons with clear and wear-resistant markings.

(2)Medical Devices: Labeling on medical catheters, plastic reagent bottles, and packaging materials with excellent biocompatibility and no chemical contamination.

(3)Food Packaging: Marking production dates and batch numbers on packaging for safety and hygiene.

3. Glass and Ceramics Industry:

(1)Glass: Surface engraving with fine patterns and micro-perforations to achieve a "glass engraving" effect without cracking.

(2)Ceramics: Fine marking on ceramic substrates and electronic ceramic components.

4..Luxury Goods and Cosmetics Packaging:

Ultra-fine logos and patterns on surfaces such as perfume bottles, lipstick tubes, and mobile phone cases enhance product quality.

5.Other Specialty Materials:

Shallow marking of paper packaging, leather, and wood (for special effects rather than depth).

Model | UV300F | UV500F | UV300 | UV301 | UV500 | UV1000 | ||

Laser parameters | Laser source model | LARK-355-3A | LARK-355-5A | SEAL-355-3E | SEAL-355-C | SEAL-355-C | SEAL-355-10S | |

Output power | 3w | 5w | 3w | 3w | 5w | 10w | ||

Beam quality m² | ≤1.2 | |||||||

Pulse repetition frequency | 20-150 kHz | 20-200 kHz | 40-300 kHz | |||||

Laser wavelength | 355nm | |||||||

0utput power stability | 3% | |||||||

Working life | About 200,000 working hours | |||||||

0pticalproperties | Marking range | 100-300mm (range optional) | ||||||

Engraving depth | ≤1mm (depending on power and time) | |||||||

Engraving speed | ≤10000mm/s | |||||||

Repeat accuracy | ±0.002 | |||||||

Minimum marking line width | 0.1mm | |||||||

Minimum character height | 0.15mm | |||||||

Use environment | Cooling way | Builtin air cooling | Extemal water cooling | |||||

System power supply | 500W/220V / 50Hz (110V can be connected) | |||||||

Temperature humidity | 0~40°, 30% RH 85%, air conditioner should be installed when used outside the range | |||||||

Oil mist condensation | Not allowed | |||||||

Other parameters | Operating system | Fly control system | ||||||

File form at | The software supports text, QR code, bar code, serial number, graphics and other marking content | |||||||

Dimensions | 660X510X1460 mm | |||||||

Packing size | Host: 850X510X280mm Water tank: 680X430X57mm Column:1350X350X280mm | |||||||

Total weight | Including cooling water tank about 89kg | |||||||

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.