In the evolving landscape of metal fabrication, SHIJIAZHUANG TOPSTAR INTERNATIONAL TRADING CO.,LTD is proud to highlight the technological prowess of the handheld laser welding machine—a game-changing tool redefining efficiency and precision in industrial welding. Designed for versatility across sectors like sheet metal processing, automotive repair, and stainless steel fabrication, this equipment merges cutting-edge laser technology with user-centric design, setting new standards for modern manufacturing.

How It Works: The Science Behind the Spark

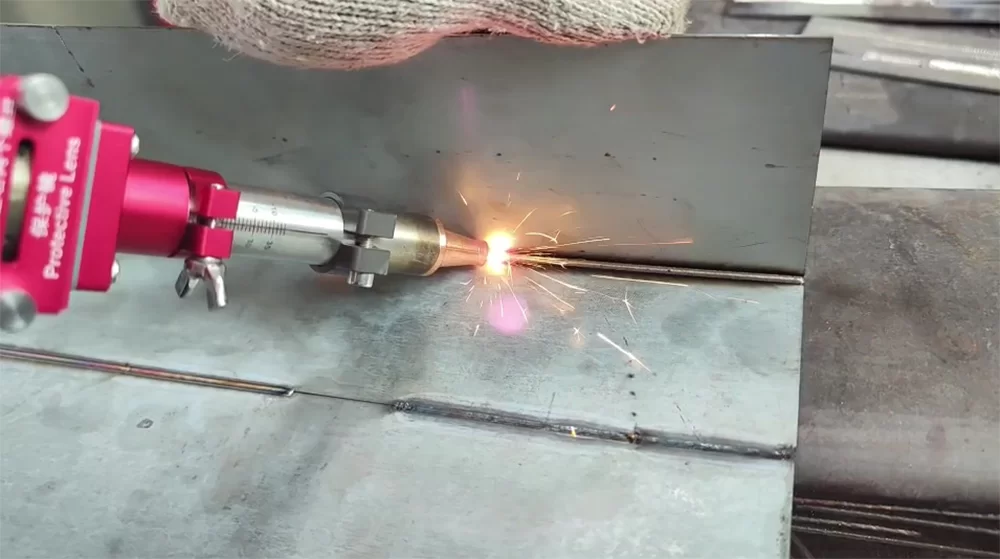

At its core, the handheld laser welding machine operates by concentrating high-energy laser beams into an ultra-fine spot (typically 0.1–0.3mm in diameter), which rapidly heats and melts metal surfaces to form strong, seamless bonds. This process relies on two key mechanisms: heat conduction welding for thin materials (up to 3mm), where energy diffuses gently to avoid vaporization, and deep penetration (keyhole) welding for thicker substrates (3–12mm), which creates a narrow, deep weld by vaporizing material to form a plasma-filled cavity. Both methods are controlled via advanced PLC systems, ensuring precise energy output—ranging from 1000W to 3000W—to match material type (stainless steel, aluminum, or titanium) and thickness.

The handheld design, featuring a lightweight welding head connected via flexible fiber optics, eliminates the constraints of fixed machinery. Operators can maneuver freely around large or irregular workpieces, from stair handrails to industrial ducts, without sacrificing accuracy. This flexibility is enhanced by adjustable swing parameters (0–5mm oscillation) that accommodate minor gaps in material alignment, a common challenge in manual welding.

Advantages Over Traditional Welding: A Paradigm Shift

Compared to conventional TIG/MIG processes, the handheld laser welding machine offers transformative benefits:

Speed & Efficiency: Welding at up to 4x the rate of TIG, it completes 1.5m of seam per minute on 2mm stainless steel—reducing production cycles for manufacturers. Its continuous operation (no need for frequent consumable replacements) minimizes downtime, while spatter-free welds eliminate post-processing steps like grinding.

Precision & Quality: The focused laser beam creates narrow, aesthetically clean seams with minimal heat-affected zones (HAZ), preventing warping in thin sheets (0.3–1mm). This makes it ideal for visible components such as kitchen appliances and elevator panels, where finish quality is critical.

Ease of Use: Unlike TIG welding, which demands years of expertise, the handheld laser welding machine requires only 1–2 days of training. Its intuitive interface, with pre-programmed settings for common materials, allows even novice operators to achieve consistent results—addressing labor shortages in skilled trades.

Material Versatility: It handles reflective metals like aluminum and stainless steel with ease, thanks to adaptive laser pulse waveforms that mitigate energy loss from surface reflection. This versatility supports mixed-material projects, from automotive parts (steel-aluminum joints) to electronics.

Safety & Sustainability: Compliant with CE and ISO 9001 standards, the equipment features low fume emissions and integrated safety protocols (including laser class 4 protection measures). Its energy efficiency—converting over 30% of input power into usable laser energy—reduces carbon footprints compared to gas-intensive MIG systems.

Real-World Impact: Applications Across Industries

From small-scale workshops to large manufacturing facilities, the handheld laser welding machine excels in diverse scenarios:

Sheet Metal Fabrication: Welding stainless steel cabinets with seamless corners.

Automotive Repair: Fixing aluminum alloy frames without distortion.

Construction: Assembling galvanized steel structures for bridges and railings.

“Adopting TOPSTAR’s handheld laser welding machine cut our production time by 60%,” shared a client in the kitchenware industry. “The precision of the welds means we no longer need to polish visible seams—saving both time and labor costs.”

As SHIJIAZHUANG TOPSTAR continues to expand its portfolio of welding solutions, the handheld laser welding machine stands as a testament to our commitment to innovation—empowering businesses to weld smarter, faster, and more sustainably. Contact our technical team to explore how this technology can transform your production line.