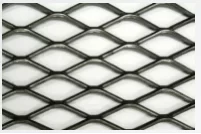

An expanded mesh making machine (also known as an expanded metal machine, expanded metal machine, stretched metal machine, or mesh drawing machine) is a type of industrial equipment specifically designed for producing expanded metal. Through a unique set of punching and stretching processes, it processes metal sheets (primarily steel, but also aluminum and stainless steel) into mesh-like sheets with continuous diamond-shaped or other shaped openings.

Expanded metal punching machines are specialized metalworking equipment that delivers high efficiency, energy-saving, and waste-free production. Through precise punching and powerful stretching, they transform flat metal into diamond-shaped expanded metal with a wide range of applications. These expanded metals, with their lightweight, high strength, slip resistance, and excellent permeability, play a vital role in various fields, including construction, industry, and transportation.

1.Waste-Free Stamping and Stretching Process

The mesh is formed by first punching a narrow slit and then performing a high-pressure stretching process, producing no metal scrap (unlike traditional perforated metal).

Material utilization is close to 100%, significantly reducing raw material costs and making it particularly suitable for processing precious metals such as stainless steel.

2.Integrated Continuous Production

The entire process, from metal coil/sheet loading to automatic feeding to precision punching to high-pressure stretching to finished product output, is fully automated and continuous, ensuring high production efficiency.

3.High Die Dependence

The die design determines the mesh shape (primarily diamond), size (short pitch SWD, long pitch LWD), and applicable sheet thickness.

Product specifications can be quickly changed by simply changing the die, providing greater flexibility.

4.Powerful Processing Capabilities

A wide range of metal sheets can be processed, including mild steel, stainless steel, aluminum, galvanized, and copper (requiring a certain degree of ductility).

A wide processing thickness range is available: typically 0.5mm to 8mm (or even thicker, depending on the machine capacity).

5.High Automation and Precision Control

PLC or CNC system control allows precise adjustment of:

Punching pitch (determines mesh density)

Stretching length and force (determines mesh size and sheet elongation)

Feed speed

Expanded metal produced by expanded metal machines has a wide range of applications, including:

1.Construction: Scaffolding treads, safety nets, building exterior wall decoration, suspended ceilings, partitions, ventilation grilles, and concrete reinforcement (expanded mesh).

2.Industrial: Equipment protective covers, platform walkways, filter screens and cartridges, silo liners, conveyor belts, and worktop panels.

3.Agriculture: Livestock cages, granary ventilation panels, and fencing.

4.Transportation: Noise barriers, anti-glare nets, and guardrails for highways and railways.

5.Furniture: Storage racks and decorative screens.

6.Other: Exhibition displays and supermarket shelves and so on.

(Thickness and width are key factors influencing equipment price. Thickness determines the tonnage of the punching machine used for the equipment. Width determines the width of the equipment. Mesh size is a key factor affecting the mold.)

Items | Grade | 160T-2000mm |

Expanded mesh making machine | Raw material thickness | 0.5-6mm aluminum |

Maxim mesh width | 2000mm | |

Mesh length intercept | 180mm | |

Punching and cutting speed | 50min | |

Total power | 30KW | |

Lubricate way | automatic oil add and automatic collect | |

Feeding method | All-in-one machine control, swing plate automatic feeding, automatic cutting, programmable, pneumatic clamp | |

Equipment | Servo motor, stepper motor, planetary reducer, ball screw, linear guide | |

Fuselage structure | The fuselage is an integrally welded gantry structure | |

Spindle | Four-point support | |

Main engine separation | Two-stage transmission plus pneumatic clutch | |

Machine size | 3900*2200*2550mm | |

Weight | 16T |

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.