Through the synergistic effect of mechanical transmission, material forming and stamping, the metal strip is processed into spiral or straight barbed wire with sharp blades.

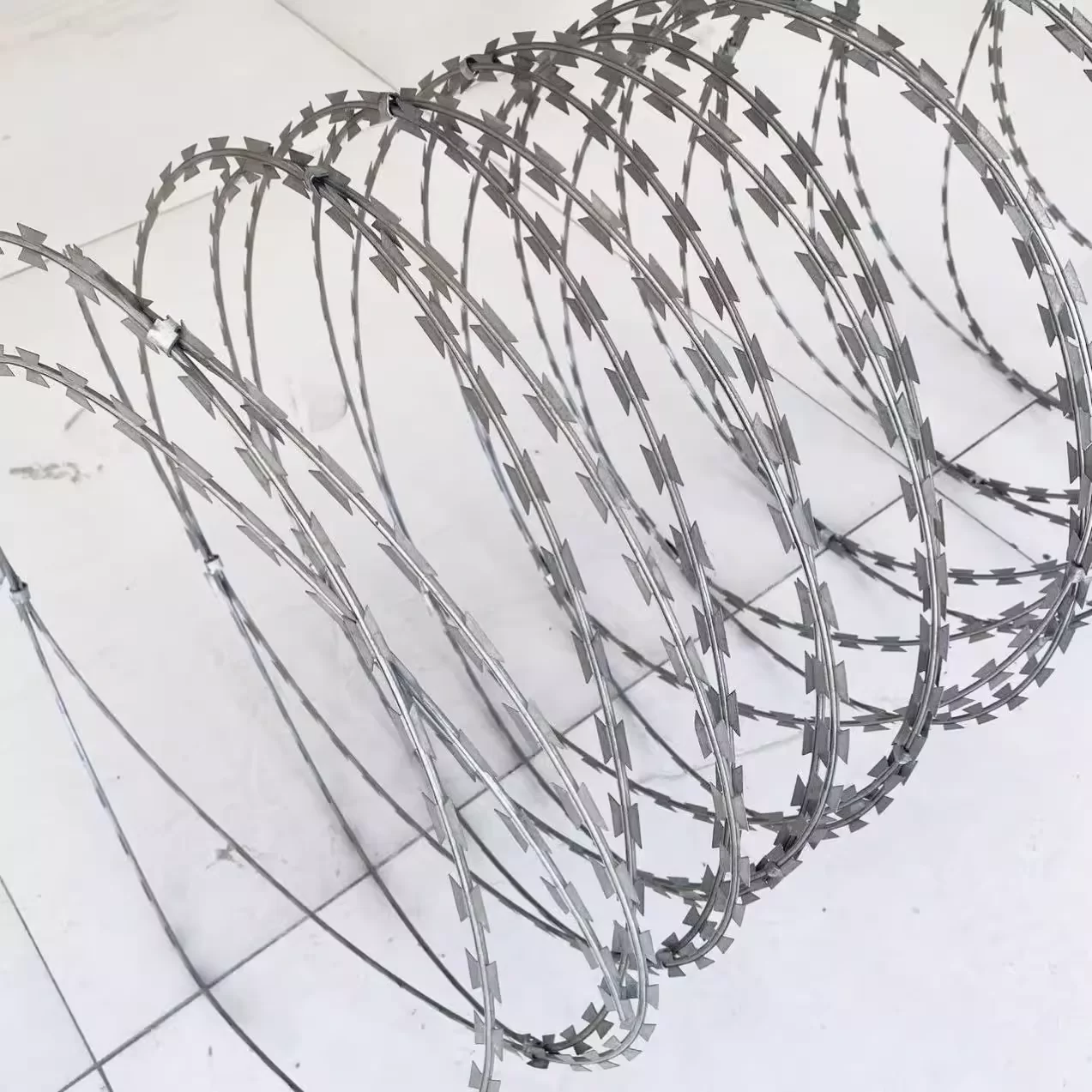

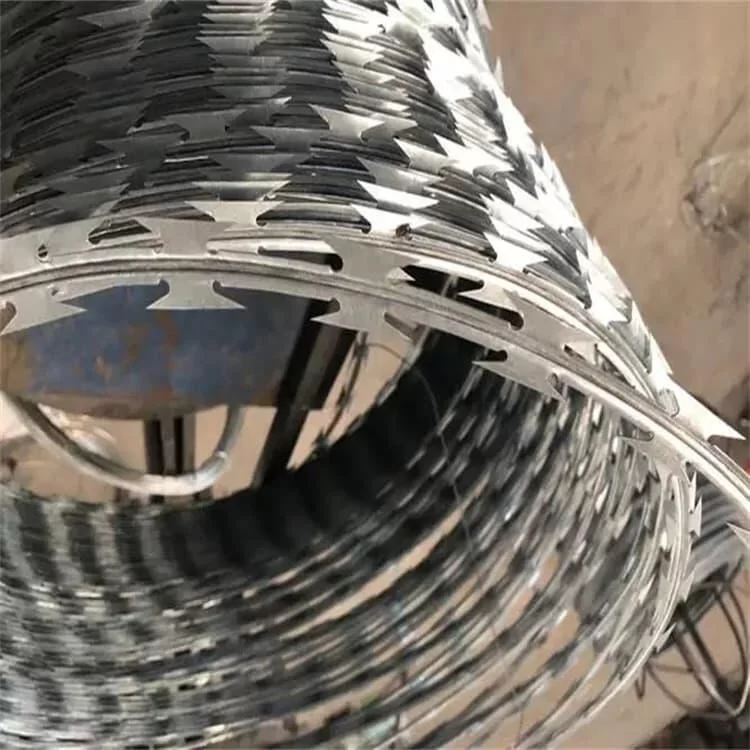

Through a mechanized process, metal strips (typically galvanized steel or stainless steel) are punched, formed, and wound into barbed wire with continuous sharp blades and a spiral structure. This razor-sharp barbed wire offers superior protection and is more efficient to install than traditional barbed wire.

1.The stamping process enables fast and continuous processing, greatly improving the production speed of razor barbed wire to meet large-scale production needs.

2.High machining precision ensures uniformity of blade size, shape, barb distance and other parameters, and good strength and consistency of barbed wire.

3.The high degree of automation reduces manual intervention and eases operation difficulty, making it easier for workers to quickly get started and control daily production.

4.It can be adjusted according to different specifications (such as blade thickness, barbed wire diameter, etc.), and various types of blade barbed wire can be flexibly produced with a wide range of applications.

5.Efficient production methods and stable quality reduce material waste and rework, while reducing labor costs, which is conducive to controlling overall production costs.

Through automated production processes, barbed wire with uniform blade spacing and stable structure is efficiently manufactured, providing a reliable physical protection barrier for various places.

Mould type | Barb Length | Barb width | Barb spacing |

BTO-12 | 12±1mm | 13±1mm | 26±1mm |

BTO-12 | 12±1mm | 15±1mm | 26±1mm |

BTO-18 | 18±1mm | 15±1mm | 33±1mm |

BTO-22 | 22±1mm | 15±1mm | 34±1mm |

BTO-28 | 28±1mm | 15±1mm | 34±1mm |

BTO-30 | 30±1mm | 18±1mm | 34±1mm |

BTO-60 | 60±1mm | 32±1mm | 96±1mm |

BTO-65 | 65±1mm | 21±1mm | 100±1mm |

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.