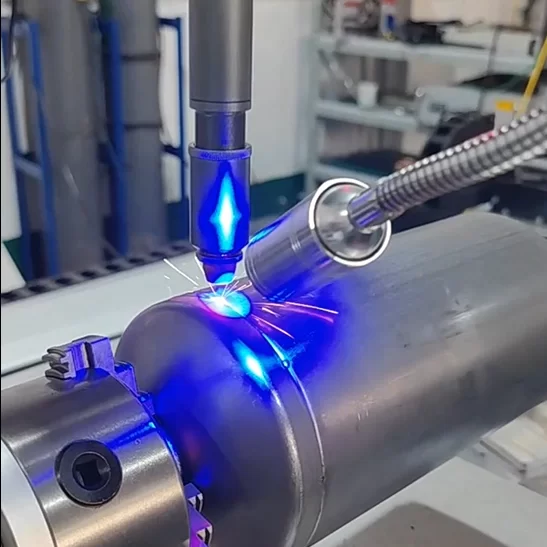

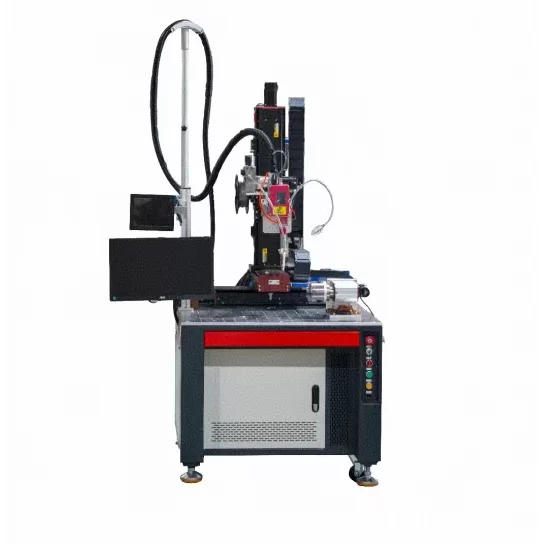

The automatic platform laser welding machine is a modern, high-end welding machine that integrates a high-precision laser source, a computer numerical control (CNC) motion system, and a vision positioning system. It uses a high-energy-density laser beam as a heat source, precisely applying it to the work piece joints to achieve instant melting and permanent connection.

The automatic platform laser welding machine solves the accuracy, deformation and efficiency problems that are difficult to overcome by traditional welding methods by perfectly combining laser technology with CNC automation, and is increasingly becoming a standard configuration in modern factories..

1.Ultra-High Precision and Quality

The laser beam spot is small (down to micron level), resulting in a minimal heat-affected zone (HAZ), aesthetically pleasing welds with minimal deformation, enabling seamless welding of precision components.

2. High Efficiency and Automation

Welding speeds are fast, eliminating the need for filler wire. Combined with an automated platform, this system enables 24/7 continuous production, significantly improving productivity and reducing labor costs.

3.Excellent Process Flexibility

Software allows for easy adjustment of parameters such as welding path, power, and speed, enabling rapid adaptation to the production needs of diverse products. This makes it particularly suitable for flexible production of small batches and high-variety products.4. High efficiency and energy saving design

4. Powerful Welding Capabilities

Capable of welding high-melting-point, high-reflectivity metals (such as gold, silver, copper, and aluminum), and capable of dissimilar welding between different metals.

5.Non-Contact Processing

No mechanical stress, no tool wear, and minimal work piece contamination.

6.Data Traceability

Advanced equipment records and stores process parameters for each weld, facilitating quality tracking and production process control.

1. New Energy Vehicles

Welding of power battery cells, modules, and packages (such as battery casings, explosion-proof valves, terminals, etc.), and precision welding of motors and electronic control systems.

2. Consumer Electronics

Welding of mobile phone mid-plates, internal components, camera modules, earphones, precision sensors, and components.

3. Medical Devices

Pacemakers, endoscopes, surgical instruments, dental implants, etc., requiring sterile, contamination-free, and highly biocompatible welding.

4. Hardware & Appliances

Precision mold repair, kitchenware, eyeglass frames, jewelry, bathroom fixtures, etc.

5. Automotive Parts

Engine parts, sensors, filters, valves, transmission gears, etc.

Items | Specification | ||

Laser Power | 1500w | 2000w | 3000w |

Welding Range | 500mm*300mm*400mm | ||

Welding Seam Requirements | Autogenous Welding: ≤15% of plate thickness | ||

Net Weight | 550kg | 570kg | 600kg |

Device Dimensions | 970*800*1700mm | ||

Welding Thickness | ≤3mm | ≤5mm | ≤8mm |

Cooling Method | Water | ||

Operating Temperature Range | 0-40°C | ||

Total Power | 10kw | 15kw | 20kw |

Voltage/Frequency | 220V, 50/60Hz (optional upon prior notification) | ||

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.