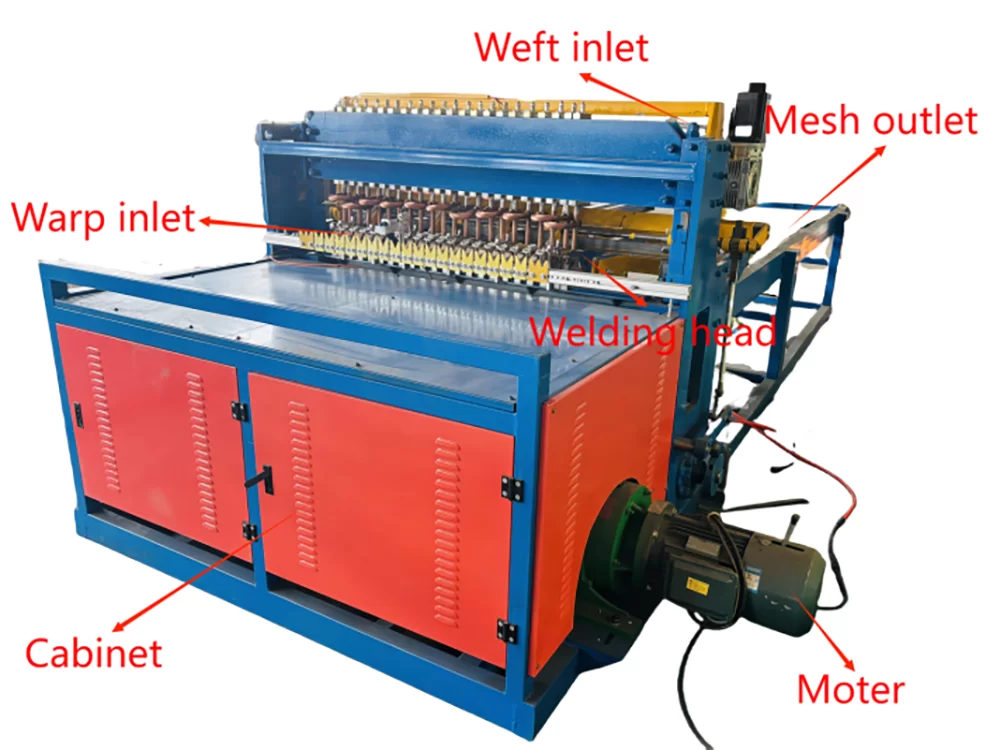

The welded mesh machine is a highly efficient and precise automated welding equipment designed for batch forming of metal mesh. It is both professional and versatile and is the core equipment for metal mesh production.

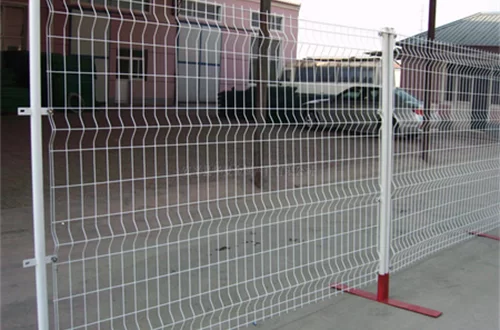

The welded mesh machine is an automated device specifically designed to weld metal wires (such as iron and steel wires) into mesh structures. It is widely used in construction, aquaculture, security, transportation, and other fields, and can produce a variety of products such as steel mesh, guardrail mesh, and aquaculture mesh. Its core advantage lies in the efficient and precise cross-welding of metal wires, replacing traditional manual welding and significantly improving production efficiency and product quality.

The automated control system continuously completes wire feeding, positioning, welding, and cutting processes, capable of producing dozens to hundreds of welds per minute. This significantly exceeds daily output by manual welding, making it particularly suitable for large-scale mass production.

A precise mechanical structure ensures accurate wire cross-positioning. Combined with controllable welding current and pressure, this ensures each weld is strong and uniform, avoiding common problems with manual welding, such as cold and leaky welds, and improving the overall strength and durability of the mesh.

Automated operation reduces reliance on manual labor, requiring only one or two workers to monitor equipment operation. This reduces labor intensity and training costs, while also preventing product quality fluctuations caused by human operator variability.

Adjustable parameters (such as mesh size, wire diameter, and mesh dimensions) allow for rapid adaptation to different product requirements without requiring frequent mold changes. This allows for diverse production scenarios and is particularly suitable for small-batch, multi-specification orders.

Using centralized power supply and efficient welding technology, the system achieves higher energy efficiency than decentralized manual welding equipment, reducing energy costs over the long term. Highly safe: The equipment is equipped with safety features such as a protective cover and an emergency stop button to reduce potential risks to operators from sparks and high temperatures during welding, complying with industrial safety standards.

The welded mesh machine can weld metal materials with good conductivity and moderate melting point, such as mild steel, stainless steel, galvanized wire and aluminum alloy. The welded metal mesh has a wide range of applications, such as in the construction industry, agriculture and animal husbandry, and other fields.

Wire diameter | 2.8-5.0mm | Wire diameter | 3.0-6.0mm | Wire diameter | 4.0-8.0mm |

Weft spacing | 25-200mm | Weft spacing | 25-200mm | Weft spacing | 50-300mm |

Warp spacing | 50-300mm | Warp spacing | 50-300mm | Warp spacing | 50-300mm |

Welding width | 2500mm | Welding width | 2500mm | Welding width | 2000mm |

Welding speed | 60times/min | Welding speed | 60times/min | Welding speed | 55times/min |

Welding point | 51 | Welding point | 51 | Welding point | 51 |

Warp wire form | Pre-cut wire | Warp wire form | Pre-cut wire | Warp wire form | Pre-cut wire |

Weft wire form | Pre-cut wire | Weft wire form | Pre-cut wire | Weft wire form | Pre-cut wire |

Rated voltage | 380V | Rated voltage | 380V | Rated voltage | 380V |

Rated power | 125KVAx6 | Rated power | 125KVAx6 | Rated power | 160KVAx6 |

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.