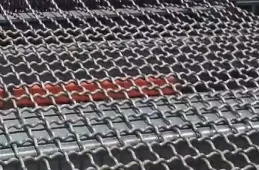

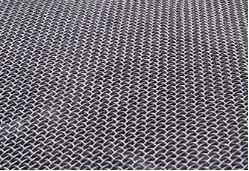

The crimped mesh machine is an automated device specialized in producing crimped wire mesh. It weaves the metal wire into mesh after pressing it into a wavy pattern using precision molds. The product is widely used in fields such as mining, petroleum, construction, and machinery protection.

The crimped mesh machine is a professional equipment in the field of wire mesh processing, mainly through the rolling-weaving process to process metal wire into mesh material with a wavy structure.

1. High precision machining capacity

(1) Micro-and micrometer-scale molding control

(2) Driven by servo motor

(3) Precision mesh processing

(4) Net pore tolerance control

2. Diversified production adaptability

(1) Material compatibility

3.Intelligent production system

(1)Intelligent control center

(2)Industrial touch screens

(3)Adaptive regulation function

4. High efficiency and energy saving design

5. Stable and reliable structure

(1)Strengthen the fuselage design

(2)Overall cast iron frame

(3)Earthquake-proof foundation

(4)Life of key components

6. Convenient operation and maintenance

(1)Humanization design

(2)Fast changeover system

(3)Centralized lubricating system

(4)Safety grating protection

1. Industrial field

(1)Filtration and screening:

It is used for liquid or particle filtration (such as vibrating screens, filter screens) in petroleum, chemical, food processing and other industries.

Ore grading screen in mining and metallurgical industry.

(2)Protection and Safety:

Make machine protective covers, ventilation fences, isolation nets, etc.

Heat-resistant mesh (e.g. boiler protection mesh) in high-temperature environments.

2. Architecture and decoration

(1)Building reinforcement:

Reinforcing mesh for concrete structures (e.g. floor heating mesh, wall reinforcement mesh).

(2)Decoration and landscaping:

Metal curtain walls, art fences, stair handrails, etc., are made with both beauty and durability.

Flower trellis and isolation fences in the garden landscape.

3. Agricultural applications

(1)Breeding and planting:

Livestock cage nets (such as chicken cages and rabbit cages), orchard protective nets.

Support nets and insect nets for greenhouses.

(2)Grain Processing:

Grain screening, dryer ventilation nets, etc.

4. Transportation and environmental protection

(1)Transportation facilities:

Highway noise barriers, bridge guardrail networks.

(2)Environmental Engineering:

Filters in sewage treatment, isolation layers in landfills.

5. Other fields

(1)Household Items:

Storage shelves, kitchen utensils (such as barbecue nets), pet cages, etc.

(For example:1.5-5mm Fully-automatic Crimped Wire Mesh Machine)

Items | Specification |

Weave width | 2100MM |

Diameter | 1.5MM-5MM |

Mesh opening range | 1.5MM-50MM |

Machine size | 3600MM*2100MM*1500MM |

Weave way | Automatic weaving |

Weave speed | 20-45times per minutes |

Servo motor | 2.6KW-2.6KW-3.8KW |

Motor brand | Jintian |

Common motor | 5.5KW-3KW |

Motor brand | Fuente |

Inverter | 5.5KW*3KW |

Inverter brand | Jintian |

Control way | PLC+Touch screen |

PLC Brand | Made in China xinjie |

Weft Ginning Machine | 4 shaft |

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.