The high temperature generated by the electric current causes the contact area between the shelf beam and the side hook to partially melt, and fuse under pressure to form a firm connection, thus achieving welding and fixation of the two.

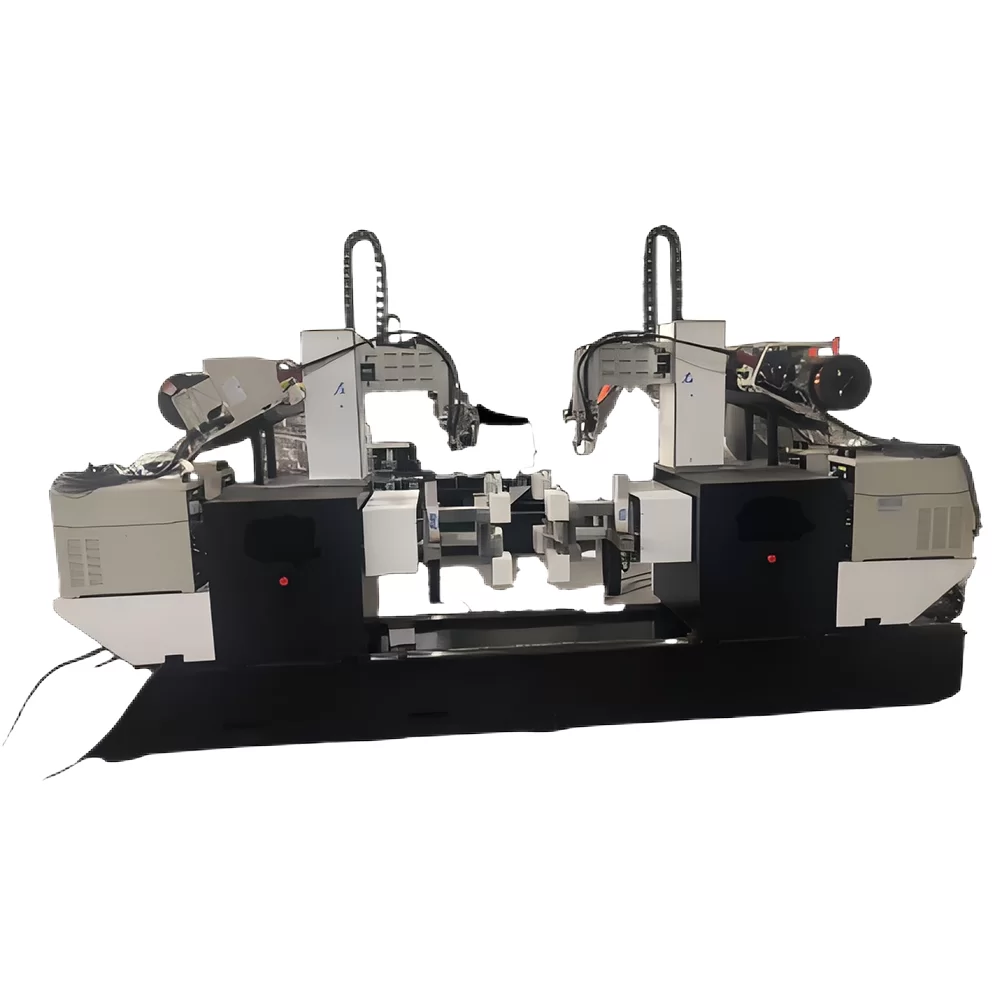

Welding machine for storage beam and side hook is a special equipment used for welding key components in shelf production. It is mainly used for the connection welding of shelf beams and side hooks. It has the characteristics of high efficiency and precision and is widely used in the field of storage shelf manufacturing.

1. The high degree of automation allows for quick completion of welding work. The output of one welding machine is usually equivalent to the output of several workers welding manually, enabling continuous and efficient production and reducing production time costs.

2. By precisely controlling welding parameters such as current, voltage and welding time, the quality and consistency of the welded joints are guaranteed, the welds are uniform and beautiful, and the welding quality is stable and is not affected by human emotions and differences in technical levels.

3. Usually controlled by PLC, the operator does not need to be proficient in welding technology. He can complete the welding task by simply setting the relevant data through the touch screen. The data can be saved and can be directly called up the next time the same model product is welded without re-entering.

4. There is no need for manual operation to hold the welding gun for a long time, which solves the problem of high labor intensity and easy fatigue of operators in manual welding and reduces the physical exertion of workers.

5. Safety devices and alarm systems, such as emergency stop buttons and protective shields, effectively isolate hazardous gases and sparks generated during welding, reducing the risk of operator injury. Some welders also feature a post-weld cooling system for added safety.

6. The system integrates multiple welding technologies to adapt to rack materials of different materials and thicknesses. By adjusting the fixture and welding parameters, it can meet the welding requirements of rack beams and lugs of different sizes and shapes.

7. The use of advanced welding technology and materials can reduce energy consumption and environmental pollution, meeting environmental protection requirements and sustainable development needs.

Welding machines for storage beam and side hook are mainly used in the production and manufacturing of storage shelves. Their core function is to achieve efficient and precise welding of shelf beams and side hooks.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.