Straighten and cutting wire machine is a special equipment used for straightening (straightening) and fixed-length cutting of steel bars, metal wires and other materials, which is widely used in construction, hardware processing, machinery manufacturing and other fields. Its core function is to straighten the bent steel bar or wire through a straightening mechanism and cut it off accurately according to the set length to achieve automated processing.

The straighten and cutting wire machines are important equipment in the metalworking industry, which can greatly improve the processing efficiency and accuracy of steel bars, wires, and pipes. It is widely used in construction, hardware processing, machinery manufacturing, auto parts production and other industries. It can efficiently straighten bent raw materials and cut them off according to preset lengths, greatly improving production efficiency and processing accuracy.

1. High degree of automation

It is controlled by PLC or CNC system to automatically complete the processes of feeding, straightening, measuring, cutting, and discharging, reducing manual intervention.

A variety of preset lengths are available for mass production.

2. High-precision machining

The length error is small, ensuring that each section of material meets the standard.

The incision is flat, no burrs, no deformation, suitable for high-precision parts processing.

3. Adaptable

It can handle steel bars, steel wires, metal pipes, etc. of different diameters.

Some models can change molds to adapt to different shapes (such as rebar, flat bar, etc.).

4. Efficient production

The cutting speed is fast, much higher than manual cutting.

Strong continuous operation capacity, suitable for large-scale steel bar processing plants or prefabricated component production.

5. Energy saving and environmental protection

Adopt inverter motors to adjust the power as needed and reduce power waste.

Hydraulic models optimize oil circuit design and reduce energy consumption.

6. Easy to operate

Touch screen control, intuitive parameter setting, low cost of worker training.

It has an automatic counting function for easy production management.

1.Construction engineering: steel cage, beam and column reinforcement, prefabricated component processing.

2.Hardware manufacturing: precision cutting of bolts, nails, springs, wires.

3.Automotive industry: straightening and cutting of suspension system parts, brake lines, metal pipe fittings.

4.Furniture industry: fixed length processing of metal brackets and steel pipe furniture.

5.Wires and cables: straightening and cutting copper wires and aluminum wires.

Item | Specification |

Wire diameter | 3.0-6.0mm |

Cutting Length | 0.8-6m,tolerance±0.2mm/m |

Drawing Speed | Max110m/min,frequency adjust |

Power supply | 415V,3phase,50HZ |

Total power | 10.5KW |

Cutting method | Servo motor system(SIEMENS) |

Material | Low carbon steel wire |

Steel surface condition | Smooth surface or galvanized or ribbed wire |

Wire loss | No |

Labor needed | 1 person |

Detailed Characteristics

1.Wire Payoff and protection frame

(1)Max loading 1000kgs

(2)Equip with air brake system

(3)Protection frame can ensure the wire feed with high speed smoothly.

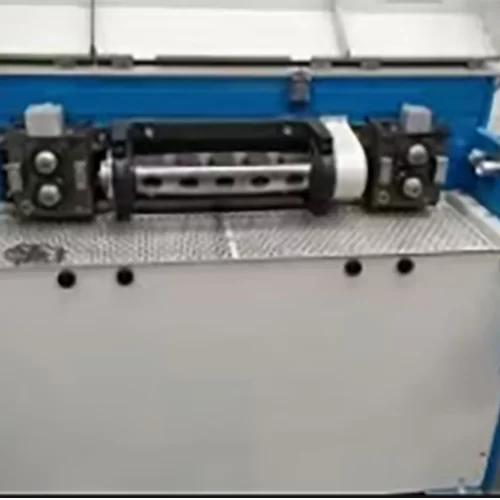

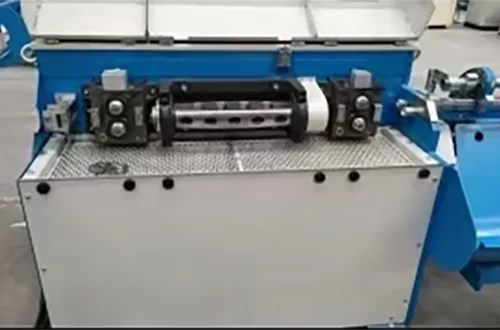

2.Main straightening unit

(1)It adopts high speed straightening roller system, which is driven by motor with big power 11KW Chinese brand

(2)Max straightening speed can reach 150m/min.

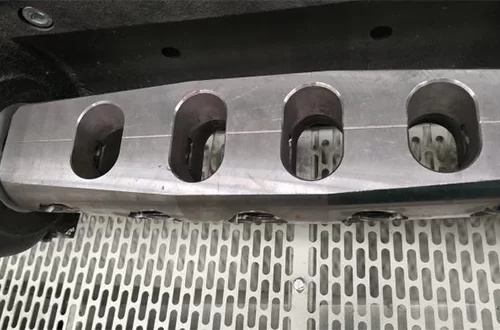

(3)In the roller , there are 10 pcs of straightening dies ( 5 pairs). Total equip 3 sets according to different wire diameters (3.0-6.0mm)

(4)Equip 2 sets of feeding rollers( 4 pcs), and adopt pneumatic pressing system.

(1)The cutting adopts servo motor system instead of pneumatic clutch, which reduce the wearing parts and with less problem .

(2)Cutting length can customized, 3m, 6m or 12m

(1)It has separate control cabinet with touch screen, and operation is more convenient and simple

(2)Adopt the counter to count the number of pre-cut wire required.Another it can clear the data at any time.

(3)When the machine has any problem in the working, it will stop automatically.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.