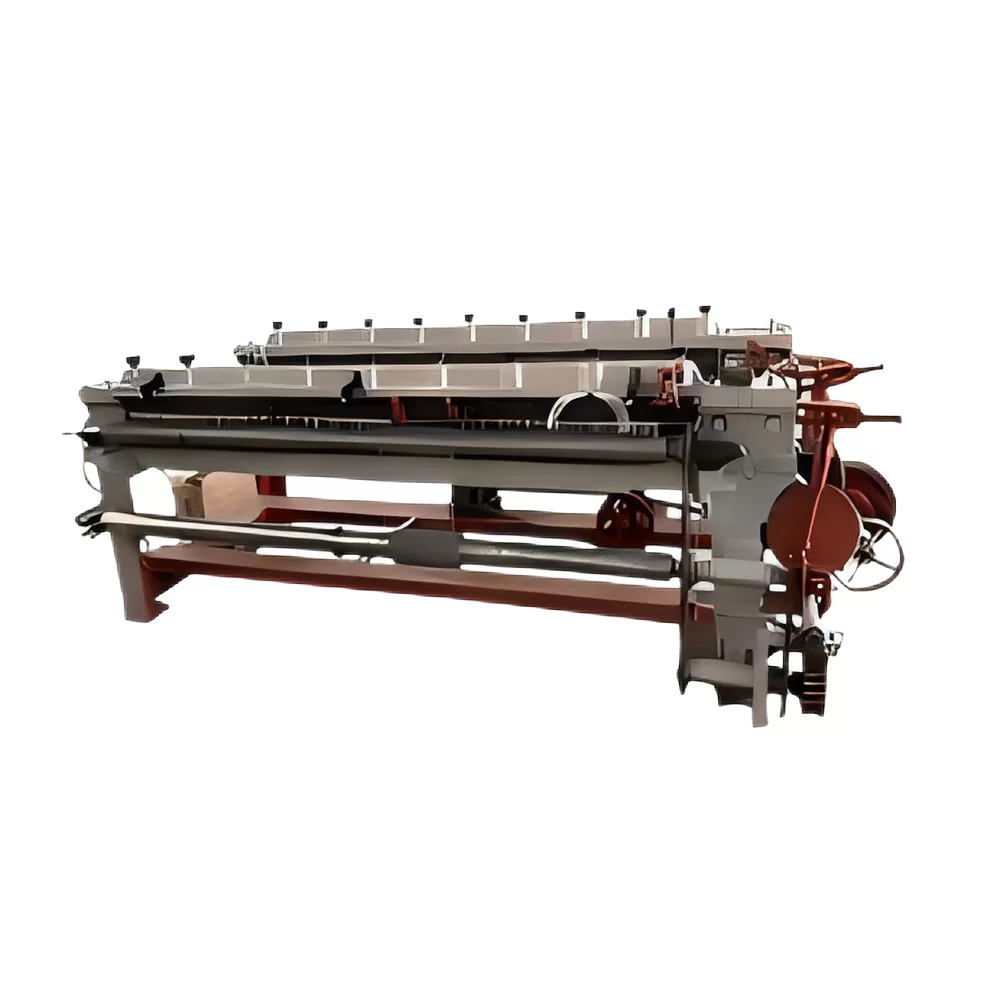

Metal wire is fed into the machine via a wire feed mechanism. After being straightened, it is then driven by a staggered weaving mechanism to weave the wire. During weaving, two sets of wires intersect at a specific angle. Driven by gears, cams, and other transmission components, the weft threads shuttle back and forth between the warp threads, entwining them and forming a continuous hexagonal mesh structure. The reeling mechanism then winds the woven mesh into a roll.

Hexagonal wire mesh machine is an automated weaving equipment specially used for producing hexagonal wire mesh (also known as twisted wire mesh, diamond wire mesh). The mesh it produces is named because the mesh holes are regular hexagonal or diamond-shaped. It is widely used in protection, breeding, construction and other fields.

1.The use of automated or semi-automated operation mode can continuously and stably complete the wire weaving process. Compared with manual weaving, it greatly improves the production speed and can meet the needs of large-scale and batch production of hexagonal wire mesh.

2.By precisely controlling the weaving parameters mechanically, the specifications of the hexagonal mesh can be guaranteed to be uniform and the mesh surface to be flat, thus avoiding problems such as uneven mesh holes and uneven tightness that are prone to occur in manual weaving, and improving the consistency and reliability of the product.

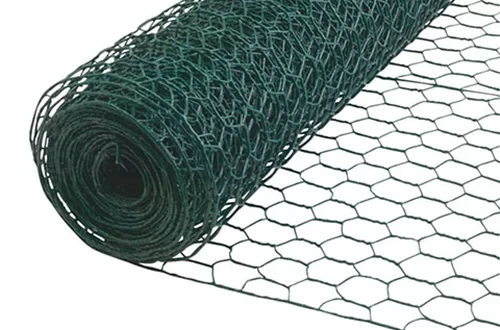

3.It can adapt to wires of different materials, and the mesh size and wire diameter can be adjusted according to needs.

4.The hexagonal wire mesh machine is equipped with a simple and easy-to-understand control system. Operators can take up their posts after simple training, which reduces the requirements for manual skills and reduces the impact of human operational errors on product quality.

5.Automated production reduces labor input and lowers labor costs; and mechanical braiding can more accurately control wire usage, reduce material waste, and effectively reduce production costs in the long run.

6.The equipment itself is mostly made of high-strength steel, and each component is reasonably designed to withstand long-term continuous work. It has a long service life and reduces the frequency of equipment maintenance and replacement.

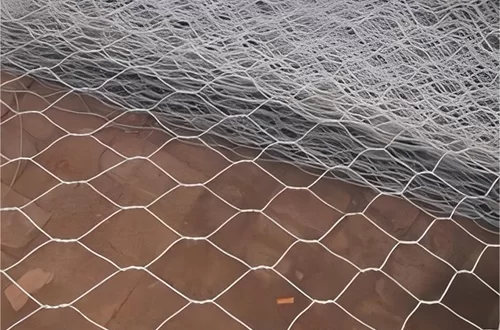

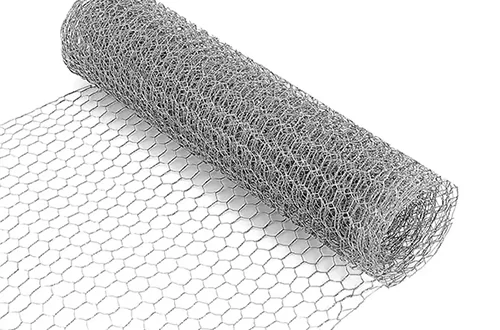

The mesh produced by the hexagonal wire mesh machine has the characteristics of stable structure, strong toughness and good water permeability. The flexibility and pressure resistance of the mesh surface can meet various needs.

Model | Width(mm) | Opening size | Wire diameter(mm) | Number of Twists | Weight | Power | Remarks | |

Mm | In | |||||||

NW12 | 1200-2300 | 12 | 3/8 | 0.38-0.5 | 3-5pcs | 2-2.5t | 2.2KW | Common models |

NW15 | 15 | 1/2 | 0.4-0.7 | |||||

NW18 | 18 | 5/8 | 0.38-0.7 | |||||

NW20 | 20 | 3/4 | 0.38-0.8 | |||||

NW25 | 25 | 1 | 0.5-1.2 | |||||

NW30 | 30 | 1.2 | 0.5-1.2 | |||||

NW40 | 40 | 1.5 | 0.4-1.5 | |||||

NW50 | 50 | 2 | 0.5-1.60 | Customized models | ||||

NW75 | 75 | 3 | 0.5-1.65 | |||||

NW100 | 100 | 4 | 0.5-2.0 | |||||

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.