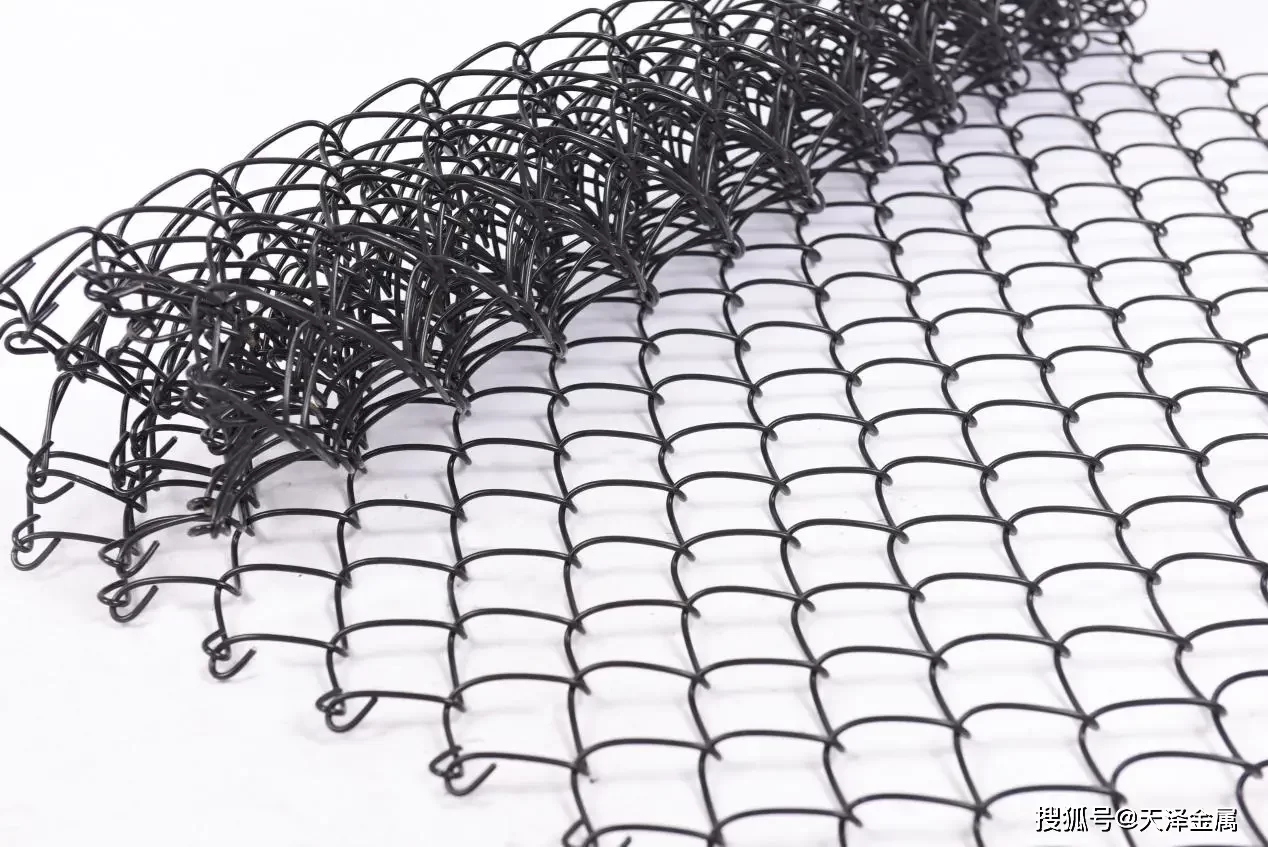

The chain link making machine efficiently converts metal wire into chain link mesh with a specific structure through the coordinated movement of the mechanical structure. It is an important equipment in the production of metal mesh products.

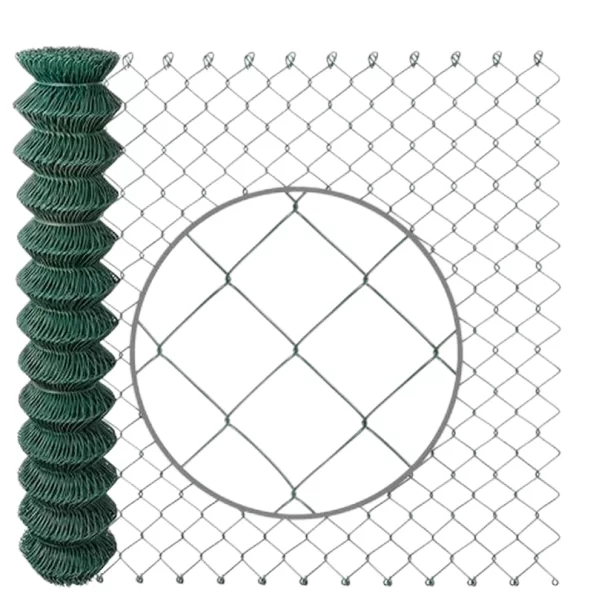

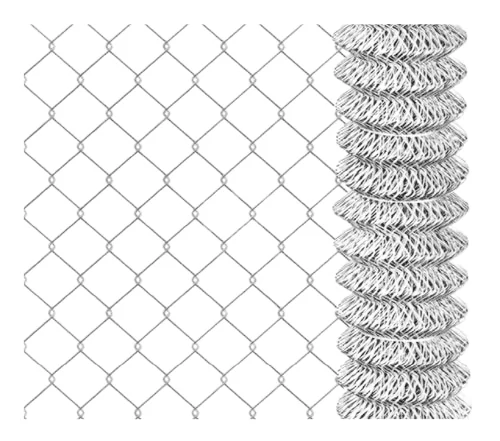

The chain link making machine's operating principle enables continuous production with a high degree of automation, making it suitable for producing coal mine support nets, stadium fencing, and aquaculture nets. The resulting mesh possesses excellent elasticity and impact resistance, a characteristic closely related to the structural properties of the diamond-shaped mesh—the mesh dissipates stress through deformation when subjected to force, making it less susceptible to tearing.

1.Chain link fence machines mostly adopt fully automatic or semi-automatic production modes, which can achieve continuous operation from feeding, weaving, cutting of raw materials (metal wire) to winding of finished products and reduce manual intervention.

2.Equipped with a PLC control system, parameters (such as mesh size, mesh width, wire diameter, etc.) can be set through the touch screen. Production can be automatically completed after one-click start, reducing dependence on operator skills.

3.Compared with traditional hand weaving, the chain link fence machine has a faster weaving speed, generally producing several meters to more than ten meters per minute (depending on the mesh size and wire diameter), which is suitable for large-scale batch production.

4.The equipment operates stably and is not prone to fluctuations in product quality due to manual fatigue, ensuring continuous and efficient output.

5.Mechanical weaving can ensure uniform mesh and smooth mesh surface, avoiding problems such as skewed mesh and uneven tightness that are common in manual weaving.

6.The tension of the metal wire is precisely controlled during the weaving process to reduce wire breakage and leakage, and improve the overall strength and service life of the product.

7.The equipment has a reasonable structure design and an intuitive operation interface, and workers can start work after simple training.

8.Key components (such as braiding wheels and wire feeding mechanisms) are made of wear-resistant materials with a low failure rate. Daily maintenance mainly includes cleaning, lubrication and replacement of wearing parts, and the maintenance cost is low.

9.Since it can produce chain link fences of different specifications, the chain link fence machine's products can be used in a variety of scenarios such as road/railway guardrails, stadium fences, zoo fences, breeding cages, mining support nets, etc., and its scope of application covers construction, transportation, agriculture, sports and other fields.

The primary function of a chain link fence machine is to weave and twist metal wires using automated or semi-automated processes, creating diamond-shaped or other mesh structures. This machine efficiently and consistently produces chain link fences of varying specifications, providing mesh products for applications such as protection, aquaculture, construction, and decoration.

Wire diameter | 1.6mm-4.0mm |

Mesh size | 30mmx30mm-100mmx100mm |

Width | 4m |

Motor | 1.Main motor:1.5KW |

Voltage | According to your need |

Output | 100-120 Square Meters/h |

Control System | PLC automatic controller |

Dimension of the machine | Main machine:1.75×0.9x1m, |

Weight | 2.2Ton |

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.